TO ACCESS THE BASE:

The plastic enclosure on the base is assembled as two halves. One side at a time can be removed to inspect for loose parts during operation. CAUTION: Do not reach into the exposed

area during operation due to the possibility of electrical shock and/or injury due to moving parts.

There are two locations on each side of the base to check for the potential cause.

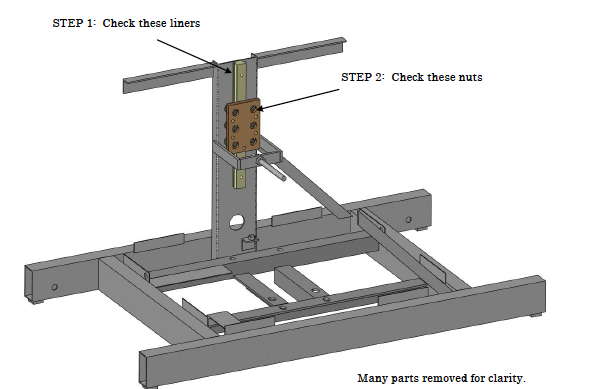

1) If there is a bump at the top OR the bottom then inspect the "V-shaped" rail that the carriage rolls up & down on. There is a narrow hardend liner that is adhered onto the face of the V track. It is the same length as the main rail so the end of it should be even with the end of the rail.

If the liner has slide up there will be a subtle bump at the bottom of the stroke when the rollers come off the end of the liner. If the liner has slid down there will be a bump at the top of the stroke. If either is the case, contact Hill Laboratories.

2. A bump at the top AND the bottom of the stroke may be caused by loose roller bearings on one or both of the carriages. There are six bearings on each carriage. Observe the carriage as the table operates. Do any of the nuts that are visible on the back surface of the carriage move at all? If so, they need to be tightened.