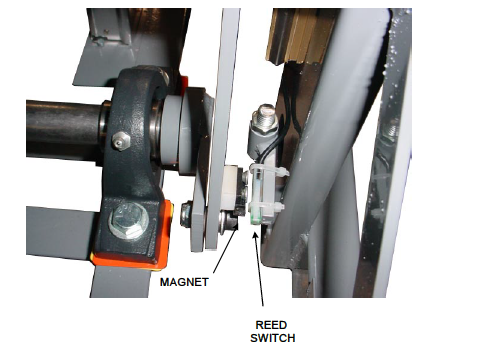

Refer to the photo.

The reed switch is actuated by the magnet. The gap between them when they are straight across from each other should be about 1/16" inch or less.

If the reed switch does not "see" the magnet then it can be carefully brought closer so that the home position can be recognized.

The assembler at the factory will start the calibration step and unplug the table when the crank with the magnet attached is at the reed switch.

The assembler swings the adjustable bracket so the magnet is against the face of the reed switch.

When he tightens the nut tolock in this position the magnet pulls away from the switch less than 1/16inch to create a close but safe gap. CAUTION: Do not turn the table on until you have verified that the magnet will not contact the reed switch when it rotates.