Tables made beginning Jan 2012

GAIN ACCESS by using the pedal to elevate the table. Remove the six screws that secure the inner section of plastic enclosure to the base and hold it up with tape or string. Photo shows one of two locations for compressor.

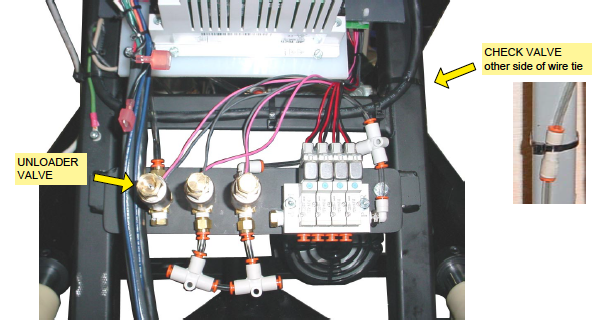

- UNLOADER VALVE - The location of the valve is indicated in the photo below. There is a hole at the top of the valve that only exhausts a quick burst of air as soon as the compressor stops. It should not leak air at any other time. If air is escaping while the compressor is running then the valve is bad, replace it. Ask for a "stand alone unloader valve" when ordering.

2. CHECK VALVE- Sometimes a bad leak can be diagnosed by air escaping out of the unloader when the compressor is not running. If that is not determined then check the valve itself. The location of the valve is indicated in the photo on the previous page. Turn the table off with air in the system. Disconnect the hose where it enters the check valve from the compressor side. The hose can be disconnected by pushing the colored ring into the fitting. Gently pull on the hose while holding the ring in. Use a little soapy water or Snoop on the end of the check valve where you removed the air hose. If it is leaking, replace the check valve.

3. FITTINGS - If the Check and Unloader valves are good then begin looking for a leak elsewhere in the system. Use soapy water or Snoop wherever an air hose enters a fitting. First try pushing the hose into the fitting. If it still leaks then remove the hose from the fitting, cut off the last half inch of hose, and reinsert the new end into the fitting .