- Select Flexion. If the pressure gauge shows between 70 to 95 poundage then the main board and compressor are working correctly.

- Select the drop again. Verify that the drop is not already cocked. We had one customer not realize that the tension knob was turned in relatively tightly which kept the drop up. The air cylinder was just pushing one side of the cushion a little more and they thought it was a weak drop.

- Check for a kinked air hose from the air cylinder back to the manifold.

- Possibly the orifice in the valve is not letting enough air through due to a small blockage. See page 2 for how to manually actuate a valve. Actuate each drop valve about 6 times. Test normal function using the pedal.

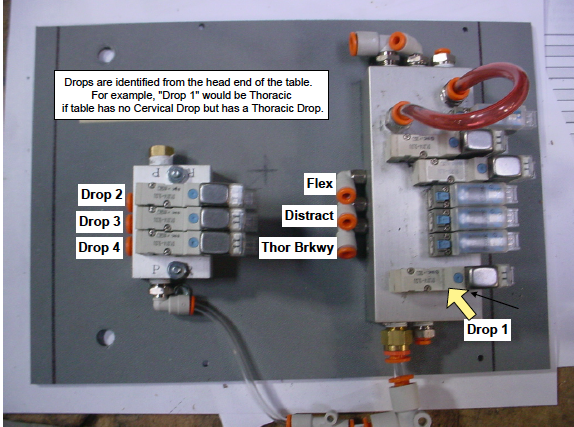

AIR FLEX- Valve Identification

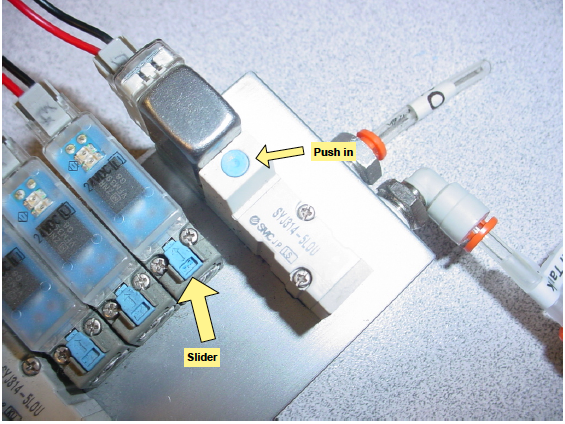

Use the drawing on the previous sheet to identify which valve controls the function which is not responding properly. There are two styles of valves. The smaller valve has a slider to manually open and close the valve and the larger version has a push button. See photo.

Use a very small screwdriver or the tip of a ball point pen to push the blue button.. Slide it and let it go several times with air in the system. This will help move a small piece of particulate that is preventing the valve from closing all the way.

The larger version of valve has a round blue button that can be pushed straight in if one of these valves is leaking. Push and let go several times to flush the valve.