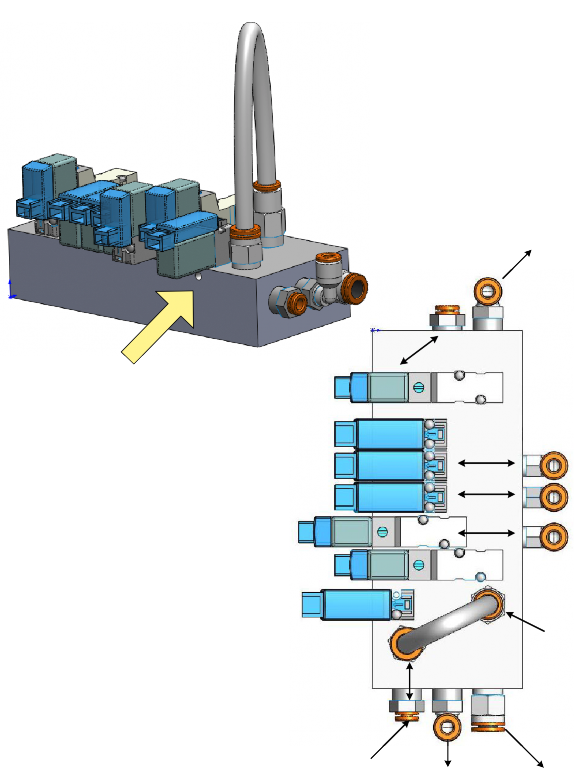

Any of the valves can be manually actuated to purge them. It is particularly helpful if the unloader valve (see arrow) is letting air past. There is a small hole in the side of the manifold, just under the unloader valve. If air comes out at any other time then when the compressor first turns off then it should be purged.

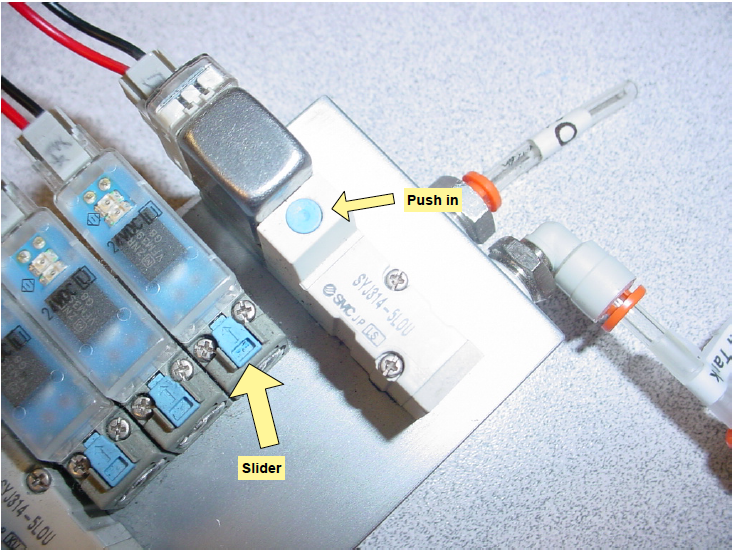

Use the drawing on the previous sheet to identify which valve controls the function which is not responding properly. There are two styles of valves. The smaller valve has a slider to manually open and close the valve and the larger version has a push button. See photo.

Use a very small screwdriver or the tip of a ball point pen to slide the blue tab in the direction of the arrow. Slide it and let it go several times with air in the system. This will help move a small piece of particulate that is preventing the valve from closing all the way.

The larger version of valve has a round blue button that can be pushed straight in if one of these valves is leaking. Push and let go several times to flush the valve.