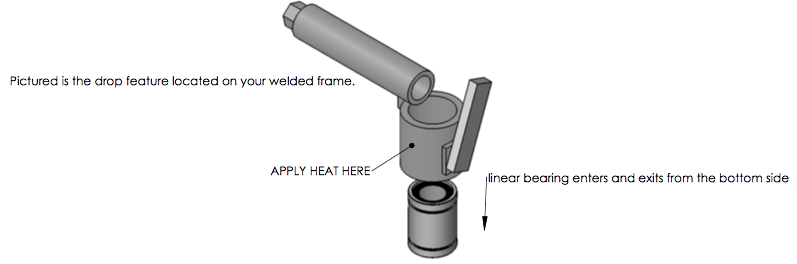

Heat must be applied to the steel tube that is holding the linear bearing.

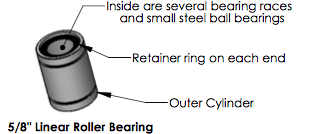

a heat gun for stripping paint can be used. This will soften the adhesive that is holding the outer cylinder of your bearing. A hammer and a steel rod , punch, or chisel will be needed to knock the cylinder sleeve out the bottom side.

A mixture of superglue and loctite need to be put on the outside of the linear bearing and inserted into the steel tube of the weldment.